Many industries use tanks to store large quantities of material that require heating and temperature regulation, including asphalt, chemical, refining, biofuel blending, and food and beverage. Tank heating coils are one of the most effective methods of heating and regulating the temperature of stored materials.

Tank heating coils are designed to be durable and efficient in maintaining the stored materials’ temperature. If the heating coil is not functioning properly, it may not be able to effectively heat the tank and its contents, leading to temperature fluctuations and potential issues with the stored materials. Therefore, it is important to ensure that tank heating coils are well-maintained and in good working order.

How Does a Tank Heating Coil Work

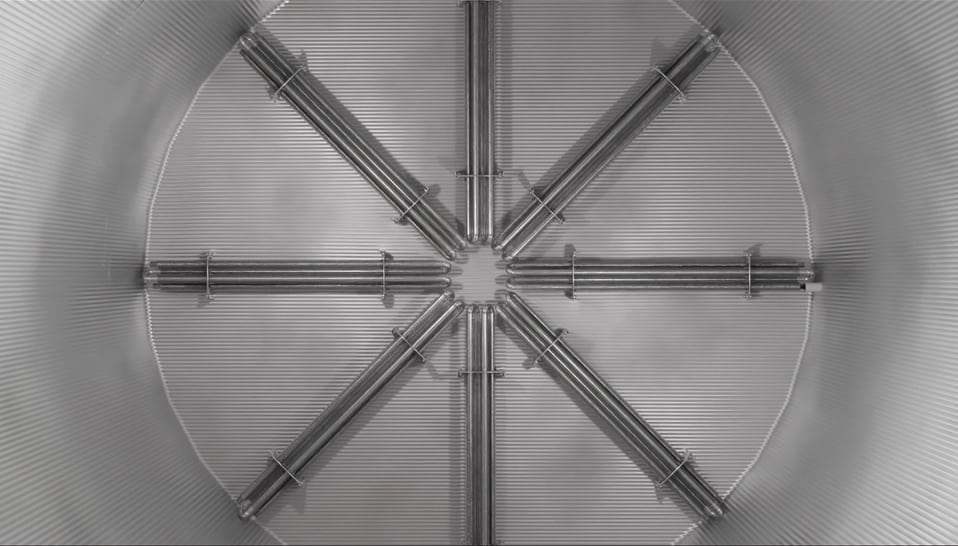

Heating coils are placed inside a tank of contents. The coils are set up in banks and then distributed evenly throughout the bottom of a storage tank. They can be made from a variety of materials, but most commonly with carbon steel or stainless steel.

The fluid (such as hot oil or steam) is pumped through a series of pipes and into the heating coil by a hot oil heater, steam generator, or other external source. This fluid continues to circulate in a continuous loop which ensures the tank’s contents remain at a specified temperature.

Finned vs. Bare Pipe Coils

Helical coils and bare pipe coils are two commonly used types of tank heating coils, but which is better suited for your particular application?

Bare pipe coils are made of a single pipe or tube. In a smaller tank where only one or two coils may be needed, the bare pipe option may be a more cost-effective option. Bare pipe coils are also a better option when the contents stored are highly viscous or for many sanitary applications.

Finned coils have thin fins welded to the bare pipe, either vertically (helically) or horizontally (longitudinally). The fins create 12x the heat transfer and efficiency over bare pipe tank heating coils.

As the tank gets larger and the heat load increases, finned coils become unmatched in efficiency when compared to the bare coil.

When comparing helically wound vs. longitudinal tank heating coils, helical coils offer even more surface area, faster heat transfer, and more even heating. With a longitudinal design, the fins are welded on horizontally which creates a shelf for the product to sit on. This increases the chance of coking and early wear.

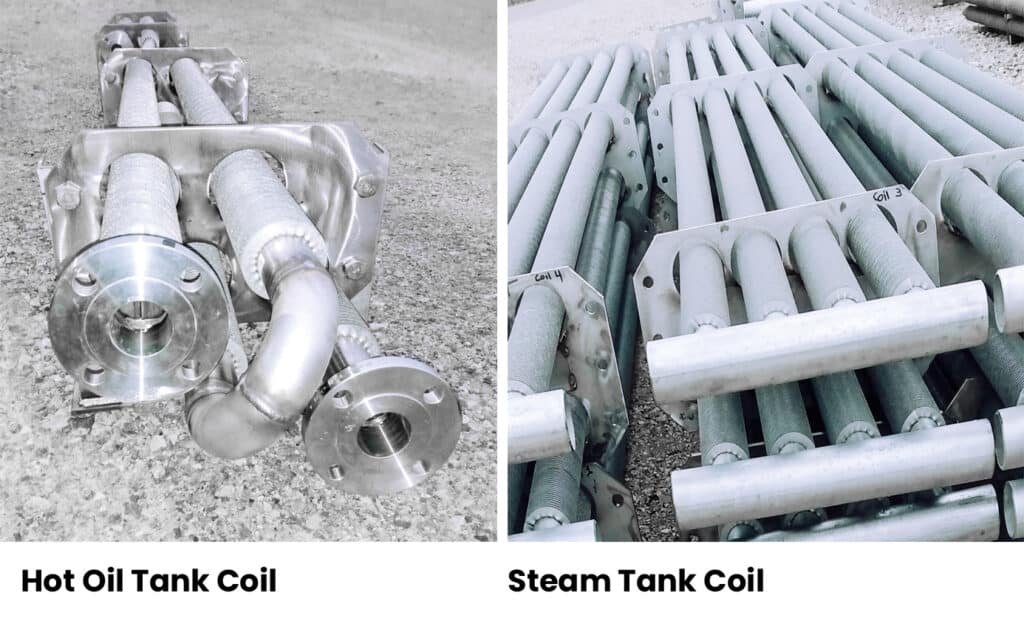

Hot Oil vs. Steam Tank Heating Coils

Hot oil coils are designed to transfer heat to the contents of a tank using hot oil as the heating media. The hot oil flows through the coils in a continuous loop, typically flowing in a serpentine fashion through the banks of coils. An industrial hot oil heater heats the oil as it passes through the coils. The hot oil then transfers the thermal energy to the stored material and circulates back through the system.

Steam coils transfer heat using steam as the heating media. Steam from a steam generator makes its way through a header in the tank coil. Steam enters the coil and flows through the bends until it returns to the header and condenses into water. As the steam passes through the pipes, it transfers heat to the stored material in the tank.

Materials of Construction

Stainless steel: Stainless steel is a corrosion-resistant material with a high percentage of chromium and is ideal for use in applications that may be exposed to corrosive materials or environments such as biofuels, food, beverage, water, and pharmaceuticals. In addition to its corrosion resistance, it’s also chosen for its visual appeal.

Carbon steel. Carbon steel is a strong and durable material that is prone to corrosion and rust when exposed to moisture but is harder and stronger than stainless steel. It is often used in more industrial applications such as refining.

Custom Steam and Hot Oil Coils from Enerquip

Tank heating coils heat and regulate the temperature of tanks containing stored materials in various industries. They are an essential component of thermal fluid heating systems, which use fluid or steam to transfer heat to the tank and its contents.

In the past, plant operators chose to heat tanks of fluid through direct-fire burners flaming into tanks of flammable contents. If that sounds dangerous, you’re right. Many plants are now turning to tank heating coils – a much safer and efficient option. Tank heating coils offer a safer alternative for heating stored materials in tanks, as they do not involve the use of flames.

Enerquip offers high-quality industrial heating equipment for plants and facilities. We specialize in the design and manufacture of reliable thermal heating systems and hot oil heating system components for various industries.

Contact us to learn more about our tank coils and how they can benefit your facility. Get a quote for our high-quality tank heating coils today.