Some new players have recently entered the industrial heating market, with a tank heating product that seems appealing, while at the same time a bit too good to be true in some ways.

Replaceable tank fins are a new solution that certainly has appeal, especially considering these fins are said to provide a number of advantages over traditional heating coils.

But are the claims about the benefits of these new replaceable tank heating coil fins really true? We take a look at this new technology and explore whether or not the benefits the manufacturers are claiming they provide are actually realistic and feasible.

What Are Replaceable Tank Heating Fins?

Replaceable tank fins are essentially aluminum fins that are bolted onto the CS pipe. They are held in place by metal bands.

These fins are intended to increase the heating surface area of a bare pipe, thus increasing the heat transfer of the system. They are also claiming to be less prone to coking, and if coking does occur, the fins can be removed and replaced instead of replacing the entire tank coil.

Do Replaceable Tank Fins Actually Provide the Benefits They Claim?

The short answer to this question is no.

As mentioned above, there are a number of supposed advantages to replaceable tank fins, including:

- Fewer coils needed

- Decreased heat times

- Increased heater efficiency

- Decreased coking

Obviously, all plant managers would ideally like to benefit from these advantages. That is why these new products have piqued the interest of facility managers in a variety of industries.

However, based on our decades of experience designing, engineering and manufacturing thermal fluid heating equipment, we have determined that these tank fins cannot actually work as described. Many of the benefits they claim to provide are just not feasible.

Why Replaceable Tank Fins for Industrial Heaters Don’t Work

There are a few key reasons why these aluminum replaceable tank fins don’t actually work.

1. The fins are not welded to the pipe

If fins are being utilized, they should be welded to the pipe in order to effectively conduct the heat. These replaceable fins are bolted on and held in place with a band that is prone to breaking, which can cause inefficient heat transfer and ultimately result in the fins falling off.

2. The fins are not made of the same material as the pipe

Fins should be made out of the same material as the pipe they are being applied to. These replaceable fins are made of aluminum, so when they are applied to CS pipes they are ineffective. Because aluminum and CS have different thermal expansions, gaps will form when heat is applied. As a result, the heat will not transfer to the fins, rendering them useless.

3. Longitudinal fins are prone to coking

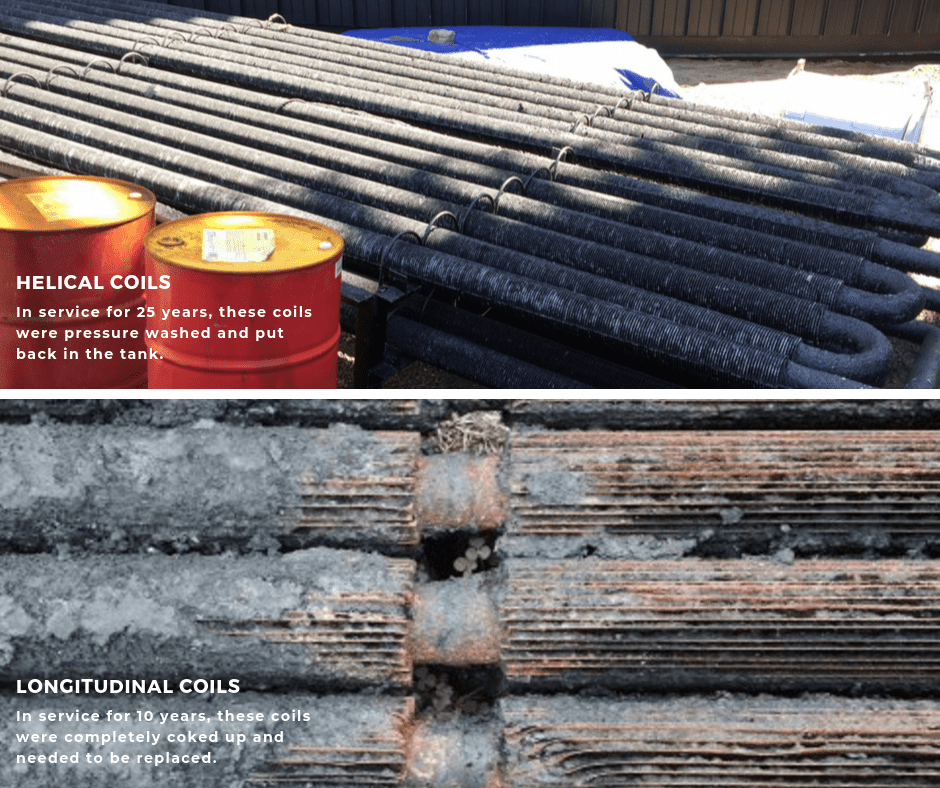

Longitudinal fins promote stagnant flow areas between the fins when placed horizontally. Though the manufacturer is claiming their design is less likely to coke, in practice their design actually makes the fins them more likely to coke. A bare pipe will not coke nearly as badly as a fin pipe, and a longitudinal finned pipe is much more likely to coke than a helical wound fin. (See images below for a comparison of helical vs. longitudinal fins.)

The key to a proper tank coil is to use a carbon steel helical wound fin product that is continuously welded to the pipe. This will provide the highest heat transfer coefficient with a coil that is much less likely to coke.

4. The heat transfer coefficient is too low

The heat transfer coefficient for a longitudinal finned pipe is about ½ that of a helically wound fin when placed horizontally in the bottom of a tank. This means it will take twice as much surface area for a longitudinal finned pipe to do the same heating as a pipe with helically wound fins.

These are just a few of the major issues that we’ve noted with the design of these replaceable tank fins. You can learn more about the false claims about these bolt-on heating fin systems here.

Thinking About Investing in Replaceable Tank Fins? You May Want to Think Again.

As facility managers are shopping their heating equipment options, some are wondering if this innovative new solution actually works. Unfortunately, though the benefits they claim to provide are appealing, they aren’t realistic.

Tempted to try these replaceable tank fins at your facility? Based on our analysis, they may not be your best bet for effective and efficient tank heating. You can delve deeper into our analysis of the impossible claims about these finned tank heating systems here.

Looking For a Trusted Tank Coil Heating Solution? We’ve Got You Covered.

At American Heating Company, we have decades of experience creating tank heating coils that are efficient and customized to meet the unique and specific needs of our customers. Our coils are among the longest lasting on the market, plus they’re manufactured right here in the USA.

We work hard to design tank heating solutions that will meet your exact specifications while exceeding your expectations.

You can learn more about our state of the art tank coil design here.

Have questions? Looking for some insight when it comes to selecting a tank heating solution that’s right for your facility? Give us a call today at (715) 748-5888 or contact us online today to get the conversation started.