Heat exchanger technology can be traced back thousands of years, with ancient heat exchangers embracing simple structures. However, they possessed a limited heat transmission ability because of limitations in production technology and scientific threshold. With the expansion of the manufacturing processes in the early 1900s came the shell and tube heat exchanger. Featuring a larger heat transfer area, these exchangers achieved greater heat transfer performance.

Shell and Tube Exchanger Design Theory

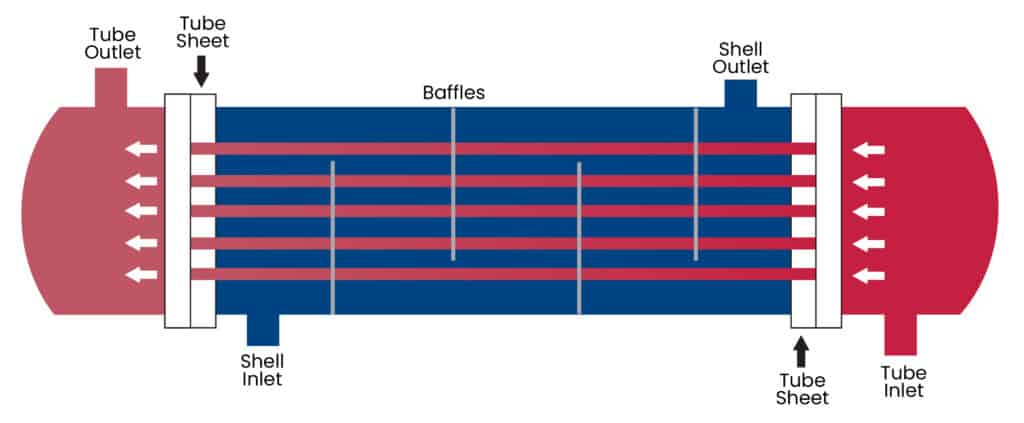

Shell and tube heat exchangers are often cylindrical-shaped and come in a wide range of sizes. They are highly versatile heat exchangers, with fluids at various beginning temperatures moving via the tubes and external shell. Their architecture allows for parallel, cross-flow, or counter-flow conditions.

While one fluid flows within the shell and outside the tubing, another fluid flows inside the tubes. The heat moves from the hot medium to the cool medium through the tube walls. It requires a broad heat transfer space for efficient heat transmission.

Besides its smaller size compared to other models, a shell and tube heat exchanger is simple to disassemble, facilitating any maintenance and repairs or cleaning.

Straight Tube Shell and Tube Heat Exchanger

Common Shell and Tube Applications

With its simple architecture, a shell and tube heat exchanger is the perfect heating and cooling option for many applications. The food and dairy industries use heat transfer to neutralize the microbial population in food and beverage populations, strengthening and extending shelf life. A shell and tube exchanger facilitates quick and efficient heat transmission and helps prevent damage to nutritional properties.

Other industrial applications for shell-and-tube heat exchangers include:

- Oil & Gas

- Pharmaceuticals

- Personal Care

- Pet Care

- Biofuels

- Cannabis

- Pulp & Paper

- Chemical Processing

- Electricity Generation

- Petrochemical

- Water

These exchangers can be used for everything from massive nuclear steam turbines to small motor oil cooling applications.

The reason shell-and-tube heat exchangers are so effective is their ability to achieve sophisticated design performance standards with a wide range of configurations. With their substantial industrial competence foundation, they can also meet demanding temperature, pressure, and mechanical design specifications.

Shell & Tube Designs vs. The Rest

When picking the appropriate heat exchanger for your applications, the operating pressures and temperatures are a key factor to consider. Other factors include product fluid qualities, available space, maintenance requirements, multi-product use of the same exchanger, and cost.

Across the world, shell-and-tube heat exchange design configuration is featured in engineering curricula. They are reasonably priced because there is less pressure loss from input to output, which reduces energy costs.

At Enerquip, we are a renowned high-quality shell and tube heat exchanger manufacturer with more than three decades of in-depth industry knowledge. We employ our design expertise to provide robust, easy-to-maintain heating and cooling gear and an ROI that surpasses our customer’s expectations. Discover more about our shell-and-tube solutions, get in touch, or request a quote today.

More from the Enerquip Blog

Considerations for Machined vs. Fabricated Channels

Understanding Finish Requirements for Shell and Tube Heat Exchangers

What’s the difference between parallel flow, counter flow and crossflow heat exchangers?

Preventing Cross Contamination in Your shell and tube heat exchangers

3 Shell & Tube Heat Exchanger Features that Affect Shell-Side Pressure Drop