Do you use a helical coil thermal fluid heater in your facility? If so, you may be frustrated by the constant burning up of your heating fluid or lengthy repair process, which over time can cost your business valuable time and money.

At Enerquip, while we do produce helical coil thermal fluid heaters for clients in need of this specific equipment, the majority of thermal fluid heaters we produce features serpentine coil technology.

Comprised of radiant coil bundles rather than wound coils, our serpentine standard thermal fluid heaters are designed and equipped to outperform and outlast competitor helical coil models. The truth is, while cost effective, the helical coil thermal fluid heaters that most industrial heating equipment manufacturers strictly produce simply can’t live up to the efficiency, lifespan, and easy maintenance of serpentine coil heaters.

3 Advantages of Serpentine Coil Industrial Heaters Over Helical Coil

1. Serpentine is More Efficient

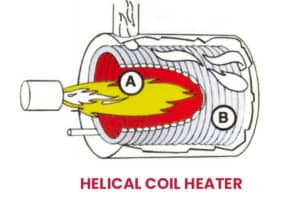

The design of helical coil hot oil heaters renders them 10% to 15% less efficient than their serpentine coil counterparts. This is because with helical coil heaters, heat is transferred by direct radiation only on the inside surface of the helical coil tubes, as seen in the drawing to the right. With serpentine coil heaters, heat is transferred to the front, sides and back of the serpentine coil, allowing for more heat distribution and operating temperatures 200-250°F higher than helical coil models. The helical coil design also leads to greater oil degradation, causing you to easily burn through your thermal heating fluid.

2. Serpentine Has a Longer Lifespan

Tube failures are more common with helical coils because the bending process used in manufacturing helical coils affects the tube wall thickness of the coil, weakening the tube and its longevity. You can expect serpentine coils to last two to three times longer than standard helical coils. In fact, it’s not uncommon for serpentine coil heaters to last 30 years!

3. Serpentine is Faster and Cheaper to Repair

The main repair obstacle with helical coil heaters is that the entire coil bundle must be replaced if there is a tube failure. With serpentine coil thermal fluid heaters, you can replace one tube at a time instead of replacing the entire coil. Often serpentine repairs can happen in a few days vs. purchasing a full replacement helical coil that can take weeks to build.

Consider Serpentine Coil Thermal Fluid Heaters For Maximum Efficiency

If you’re contemplating your options, consider our innovative serpentine coil technology that will last longer, run at a higher operating temperature, and is more easy to maintain. All of these serpentine coil benefits can help your facility to operate more efficiently – something helical coil heaters simply can’t offer.

Leaning towards a serpentine coil thermal fluid heater for your facility? At Enerquip, all of our standard thermal fluid heaters feature serpentine coils. Learn more about our serpentine coil thermal fluid heaters!

Curious about the benefits of going with a serpentine coil heater? Get the details and specifics about the advantages of a serpentine coil heater design here.

Give us a call at (715) 748-5888 or contact us online for more information.